Wenalytics for QSR and Restaurant

Run Leaner, Smarter, and Always On

In the fast-paced world of quick service restaurants, every second counts. Equipment downtime, rising utility costs, and inconsistent food quality can erode margins and customer trust. That’s where Wenalytics comes in.

Our all-in-one Computerized Maintenance Management System (CMMS) with integrated IoT sensor technology is purpose-built for QSRs—helping you monitor, manage, and optimize operations across every location in real time.

Key Benefits for QSR and Restaurant

Reimagine Facility Intelligence to Power Better Results

At Wenalytics, we unify fragmented equipment, siloed systems, and disconnected workflows into one cohesive digital ecosystem. From utility data to maintenance logs, from inventory to vendor coordination — we bring it all together. Our platform becomes the connective tissue across operations, laying the groundwork for a more intelligent, automated, and responsive facility strategy.

Build a Digital Foundation with Compounding Returns

We help you go beyond isolated fixes to establish a scalable digital backbone for your operations. By aligning physical assets, real-time insights, and stakeholder actions under one interface, Wenalytics drives a multiplier effect — unlocking cost efficiencies, operational resilience, and continuous improvement across your entire portfolio.

Frequent Repair Issues:

- Not cooling (unit “too warm” – often due to compressor or coil icing); Ice/frost buildup on evaporator; Door gasket leaks causing warm air ingress.

Recommended IoT Sensors:

- Temperature sensors (inside cooler/freezer)

- Door-open sensor

- Refrigerant pressure sensor

Sensor Utility:

- Alerts if internal temp rises above safe range (prevent food spoilage); Detects if door is left ajar; Monitors refrigerant pressure to catch leaks early (prevent compressor failure).

Frequent Repair Issues:

- Not harvesting ice (machine runs but no ice drops – ~44% of issues) due to frozen evaporator or water supply issues; Water leaks (hose/inlet or drain clogs); Error codes indicating component failures.

Recommended IoT Sensors:

- Temperature sensors (evaporator coil)

- Water flow sensor (or level sensor in bin)

- Leak detector

Sensor Utility:

- Senses abnormal icing (temp stays too low/high on evaporator) to prompt defrost or maintenance; Detects if water flow drops (clogged filter or supply off); Leak detector catches overflowing drain or line leaks early.

- Not cooling adequately (37% of HVAC incidents) – often caused by refrigerant leaks or condenser failures; Leaks (water leaking from AC – e.g. clogged condensate drain); Not heating (burner or heating element issues).

Recommended IoT Sensors:

- Thermostat sensors (smart thermostats with temp/humidity)

- Current/Power meter (for compressors/fans)

- Refrigerant pressure sensors and vibration sensors (on condenser unit)

Sensor Utility:

- Continuously tracks ambient temp vs. setpoint – sends alert if AC can’t maintain target (signals a cooling problem); Monitors compressor and fan electrical load – erratic amp readings can flag a failing motor (predictive alert before a breakdown); Refrigerant pressure trends reveal slow leaks before cooling loss; Detects excessive vibration in HVAC unit (indicates fan imbalance or impending motor fail).

- Poor cleaning (dishes not coming out clean due to spray arm clogs, low wash pressure, or low wash temp); Leaking during operation (worn door seals, cracked hoses); Not draining (clogged drain or pump failure leading to floods)..

Recommended IoT Sensors:

- Water temperature sensor (in wash tank)

- Water pressure sensor (on wash and rinse lines)

- Leak sensor (under machine)

- Current sensor (on wash pump motor)

Sensor Utility:

- Ensures wash water reaches sanitizing temperature (alerts if below spec – heater may be failing); Monitors spray pressure – a drop can indicate a clogged nozzle or pump issue; Leak sensor catches drips or floods under machine early; Pump motor current draw is tracked – a spike might signal a jammed impeller or an impending motor failure (enabling proactive fix).

- Leaks in plumbing lines or fixtures (over 30% of plumbing calls) – leaky faucets, pipe joints, etc.; Clogs/Backups – e.g. clogged drains or toilets causing backups (drain clogs ~18% of issues); Fixture parts failures (e.g. broken faucet cartridges or flush valves).

Recommended IoT Sensors:

- Water flow meter (on main and branch lines)

- Water leak sensors (on floors under sinks, near toilets, etc.)/li>

- Drain flow sensor or smart level sensor (in floor drains/sewer clean-outs)

Sensor Utility:

- Flow monitoring detects continuous flow or abnormal usage when water should be off (flags hidden leaks or a running toilet valve); Leak detectors give instant alert of water on floors (pipe burst or overflow) – preventing water damage; Smart drain sensors warn of slow draining or high water in floor drains (catch clogs before an overflow).

Frequent Repair Issues:

- Heating failures – burner/pilot or element not igniting (no heat); Oil filtration clogs (pump or filter blocked, oil not filtering); Thermostat malfunctions causing incorrect oil temp (too hot or too cool).

Recommended IoT Sensors:

- Oil temperature sensor

- Pressure sensor (in filtration line or pump)

- Current/vibration sensor (on gas valve or fryer burner blower)

Sensor Utility:

- Monitors oil temp trends to ensure proper heating (alerts if out of range to prevent undercooked or burnt food); Detects rising pressure or vibration in pump (indicates clog or wear for predictive maintenance); Senses ignition cycles and can flag failed ignition attempts (prevent surprise fryer downtime).

- Poor airflow or smoke buildup (from grease-clogged filters/ducts); Exhaust fan motor failures or belt breaks (fan not running); Excess grease accumulation creating fire risk.

Recommended IoT Sensors:

- Airflow sensor or differential pressure sensor (across hood filters)

- Vibration sensor (on fan motor)

- Grease level sensor (in drip trays or ducts)

Sensor Utility:

- Alerts if airflow drops below normal (indicating clogged filters or fan outage); Vibration/amp monitoring of fan motor to predict failure (e.g. bearings wear – vibration increases); Warns when grease trap or hood grease cup is full to schedule cleaning (fire safety).

- Uneven or insufficient heating (fails to reach set temp due to faulty heating elements or calibration); Ignition/pilot problems in gas ovens (pilot won’t stay lit); Worn door seals causing heat loss.

Recommended IoT Sensors:

- Temperature probes (multiple zones inside oven)

- Gas leak detector (near oven if gas-fired)

- Door sensor (door seal status by sensing proper closure)

Sensor Utility:

- Verifies oven temperature uniformity and alerts if unable to hold setpoint (indicating element or thermostat issue); Gas sensor for safety—alerts on any gas leakage; Door sensor can indicate a poor seal or door left open (energy waste and uneven cooking).

- Overheating (almost half of calls are unit running too warm)

- Worn door gaskets or hinges (parts replacement)

- Water leaks (from clogged drain or melting ice).

Recommended IoT Sensors:

- Temperature sensor (inside unit)

- Door-open sensor

- Leak detector (pan or floor)

Sensor Utility:

- Continuous temp monitoring with instant alerts if out of range; Notifies if door is frequently open (staff training or gasket fix); Leak sensor spots drain backups or condensation overflow before flooding.

- Outlet issues – burned out or overloaded outlets (often need replacement or new install – ~21.8% of electrical service)

- No power to equipment (tripped breakers or GFI, ~12% of issues)

- Lights out (burnt bulbs or fixture wiring problems)

Recommended IoT Sensors:

- Smart power meters or smart breakers (monitor circuit load per circuit/outlet)

- Temperature sensors (in electrical panels or at critical outlets)

- Lighting sensors (smart occupancy or photocell sensors for lights)

Sensor Utility:

- Energy monitoring per circuit detects overloads or unusual draw – can send alerts before breakers trip and identify over-amped circuits

- Thermal sensors in panels/outlets catch overheating connections (prevent electrical fires by flagging a scorched outlet early)

- Smart lighting sensors report lamp failures or excess energy use (e.g. a flickering ballast) and can reduce energy costs by ensuring lights are off when not needed.

- Leaks (syrup or water leakage at fittings – ~22% of dispenser issues)

- Not dispensing drinks (no flow – pump failure, empty syrup, or ice maker issue)

- Mix ratio or carbonation problems (flat soda due to CO₂ supply)

Recommended IoT Sensors:

- Flow sensors (on syrup and water lines)

- Pressure sensor (CO₂ tank regulator or syrup pump)

- Leak sensor (in dispenser cabinet drip pan)

Sensor Utility:

- Flow sensors verify each dispense has proper volume – can detect a blocked nozzle or empty syrup bag when flow drops (alert staff to replace syrup)

- CO₂ pressure sensor signals low gas pressure before drinks go flat (preemptively replace CO₂ tank)

- Leak sensor in the machine cabinet catches leaks from lines or valves to avoid sticky messes and equipment damage.

- Burners not igniting or only partial flame (due to clogged jets or faulty igniters)

- Not heating (nearly 1/4 of issues – e.g. pilot out or gas supply off)

- Broken knobs or valves (parts replacements)

Recommended IoT Sensors:

- Thermocouple/Temperature sensor (surface temp monitoring)

- Flame sensor or optic sensor (to confirm burners lit)

- Smart knob sensors (detect if a knob is present and in correct position)

Sensor Utility:

- Surface temp sensor spots sections not reaching target heat (sign of burner or thermostat fault)

- Flame detection can trigger re-ignition or alert if a burner fails (prevent gas buildup)

- Detects missing or broken knob and can notify maintenance (avoiding manual workarounds).

- Insufficient hot water (water not heating or slow recovery – often a bad heating element, gas burner or thermostat)

- Leaking tank or valves (puddle around heater)

- Sediment buildup causing noise and reduced capacity.

Recommended IoT Sensors:

- TTemperature sensor (on hot water outlet)

- Water leak sensor (floor at heater base)

- Pressure sensor (tank pressure or relief valve monitor)

Sensor Utility:

- Flags if outlet water temp drops below setpoint or fluctuates (early sign of element or burner issues, so maintenance can be scheduled)

- Floor leak sensor instantly warns of a tank leak (avoids catastrophic flood and allows timely replacement)

- Pressure sensor or smart relief valve monitors abnormal pressure spikes (preventing unsafe conditions and energy waste from stuck valves).

Smart Sensors. Smarter Stores.

Our plug-and-play IoT sensor suite monitors:

All sensor data feeds directly into your Wenalytics dashboard—giving you a single pane of glass to detect anomalies, schedule maintenance, and protect your brand in real time.

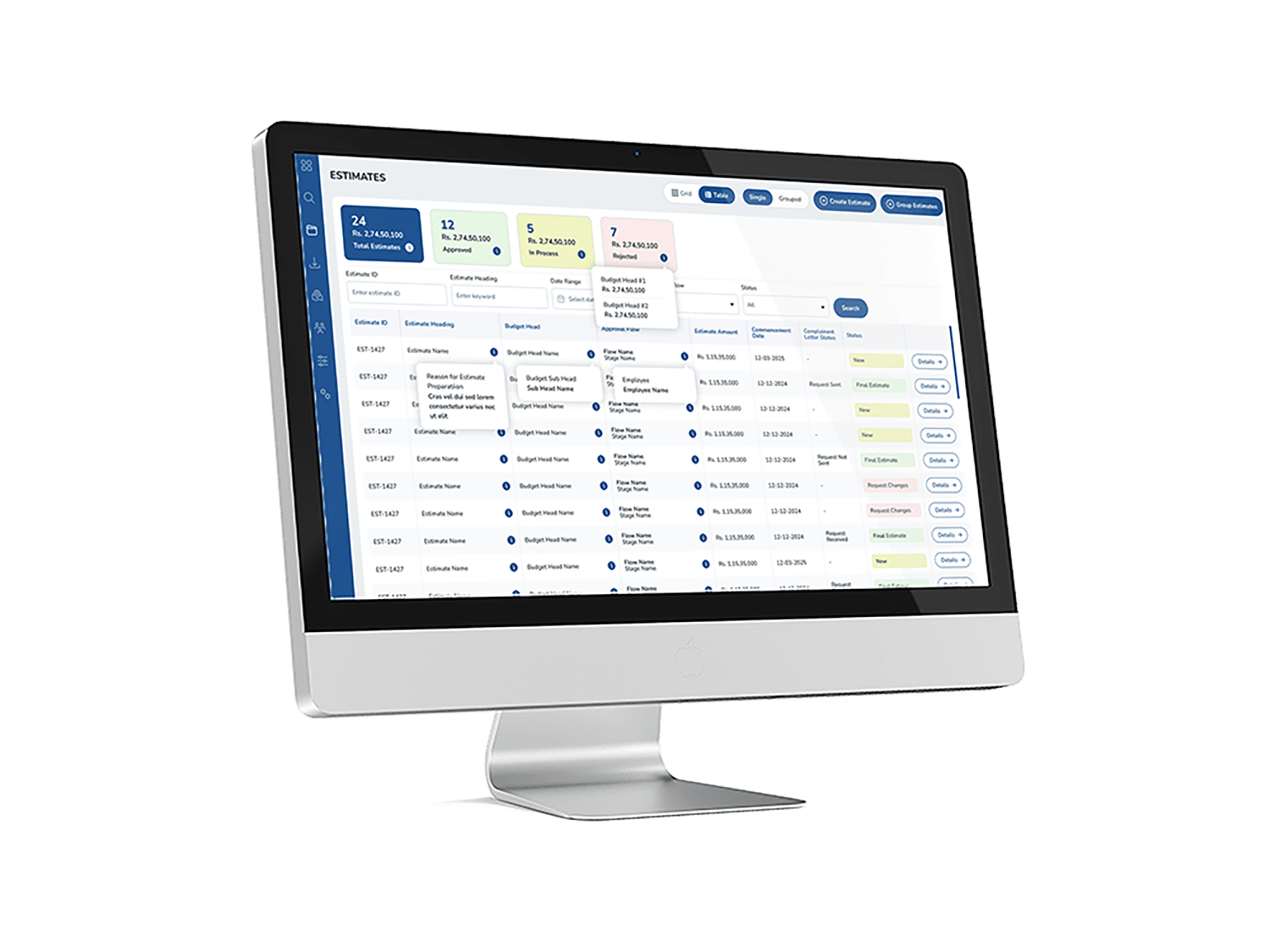

Platform Highlights

Role-Based Mobile App for Location Teams

Trusted by Facility Teams, Ops Leaders & Franchisees Alike

Whether you’re managing 5 or 500 locations, Wenalytics scales with your brand—delivering Ready to protect margins, boost uptime, and automate your QSR maintenance strategy?